Water jet Loom

Price 300000 INR/ Piece

MOQ : 1 Piece

Water jet Loom Specification

- Glue Type

- No glue required

- Dimension (L*W*H)

- 3600 x 1500 x 1800 mm

- Driven Type

- Electric

- Output Frequency

- 50 Hz

- Function

- Weaving fabric using high-pressure water jet

- Weight

- 1800 kg

- Lubrication System

- Centralized automatic lubrication

- Reed Width

- 190 cm

- Water Pressure

- 0.2 - 0.4 MPa

- Weft Selection

- Up to 6 colors

- Humidity Range

- 40% to 85% RH

- Nozzle Diameter

- 1.3 mm

- Main Motor Power

- 2.2 kW

- Max Speed

- 900 RPM

- Shedding Type

- Dobby / Cam / Jacquard

- Ambient Temperature Range

- 5°C to 40°C

- Automatic Stop Devices

- Yarn detector, warp break sensor

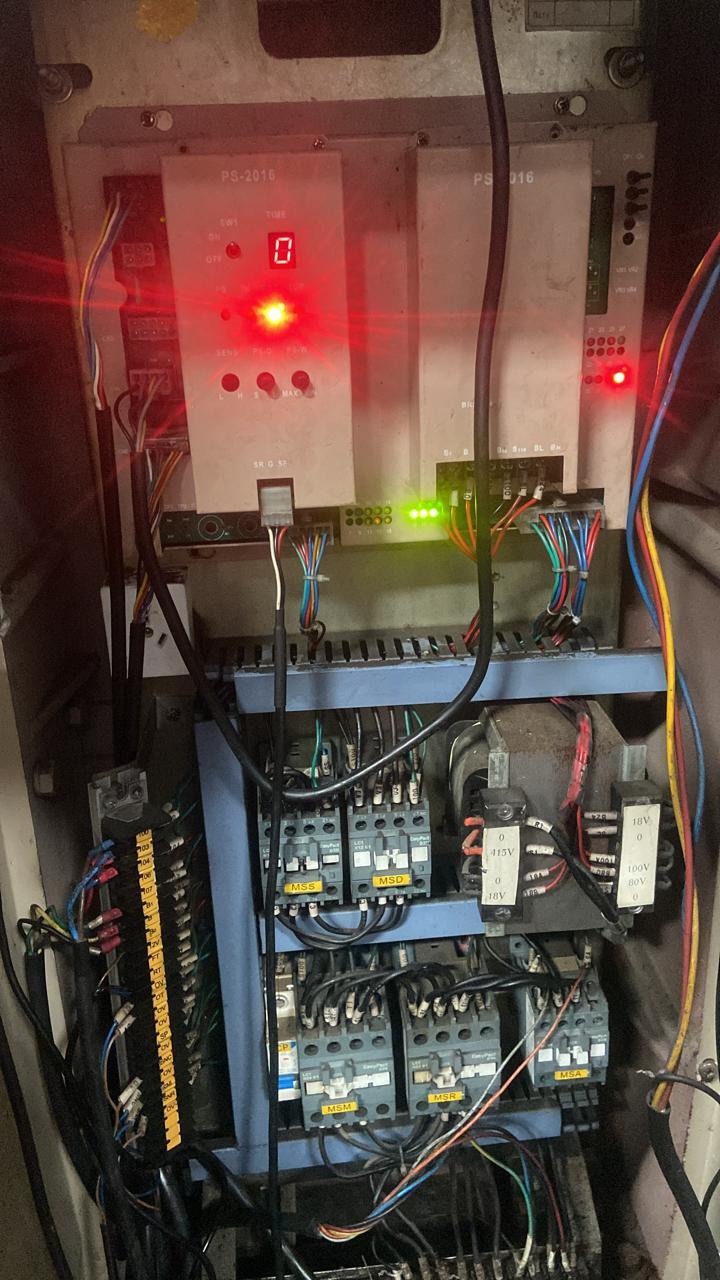

- Control System

- PLC with touch screen

About Water jet Loom

water jet loom is similar to an air jet loom but uses water instead of air to transport the yarn around the shed. Water jet looms can weave very quickly whilst the yarn is not damaged as water is less abrasive than solid matter moving the yarn around (like it is with rapier weaving looms).Innovative High-Speed Weaving

Designed to reach speeds up to 900 RPM, this Water Jet Loom offers rapid fabric production without compromising quality. The combination of a robust main motor (2.2 kW) and precise water pressure control (0.2-0.4 MPa) drives superior performance, while multiple shedding types-Dobby, Cam, or Jacquard-accommodate a diverse range of textile requirements.

Advanced Automation and Safety

Automation ensures operator convenience and fabric integrity, with a PLC touch screen providing intuitive control. Yarn detectors, warp break sensors, and an automatic stop device reduce manual intervention, prevent defects, and minimize waste. Centralized automatic lubrication simplifies maintenance, extending machine life.

Flexible Operation and Application

Supporting up to 6 weft colors and operating efficiently across wide temperature (5C-40C) and humidity (40%-85% RH) ranges, the loom is ideal for various environments. Requiring no glue, it's suitable for environmentally conscious manufacturers and produces textiles for apparel, home furnishings, and industrial uses.

FAQ's of Water jet Loom:

Q: How does the Water Jet Loom operate to weave fabrics?

A: The loom uses a high-pressure water jet to insert the weft yarn across the warp threads, powered by an electric drive. This process is monitored and controlled via a PLC touch screen, ensuring precise weaving with minimal operator intervention.Q: What types of shedding systems are available with this loom?

A: This loom is compatible with Dobby, Cam, and Jacquard shedding mechanisms, allowing it to produce a wide variety of woven patterns and fabric textures depending on production needs.Q: When is centralized automatic lubrication beneficial for loom operation?

A: Centralized automatic lubrication is most beneficial during continuous and high-speed operation, as it reduces manual maintenance needs, prevents excessive wear, and extends equipment lifespan by ensuring consistent lubrication of all necessary components.Q: Where can this Water Jet Loom be installed and operated effectively?

A: The loom is designed to function optimally in environments with ambient temperatures ranging from 5C to 40C and relative humidity of 40% to 85%, making it suitable for a variety of textile mills and production facilities.Q: What is the process for changing weft colors during production?

A: The PLC control system enables weft selection of up to 6 colors, allowing operators to switch between different weft yarns during the weaving process seamlessly, facilitating the production of multi-colored fabrics with efficiency.Q: What benefits does the yarn detector and warp break sensor provide?

A: These automated features immediately detect yarn or warp breaks, triggering the loom to stop. This reduces fabric defects, minimizes downtime, and saves material by alerting operators to address issues instantly.Q: How does the loom contribute to efficient and environmentally friendly textile production?

A: By using water jets instead of glue, and supporting centralized lubrication, the loom reduces reliance on chemical adhesives and manual processes-promoting cleaner, more sustainable manufacturing while maintaining high productivity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Textile Machinery Category

Teaser Willow Machine

Price 200000 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 1850 mm x 1100 mm x 1200 mm

Driven Type : Electric motor driven

Weight : Approx. 700 kg

Function : Opening and cleaning fibers such as cotton, synthetic, and other textile fibers

Carding machine

Price 1000000 INR

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 3500 x 1200 x 1800 mm

Driven Type : Electric

Weight : 1800 kg

Function : Carding of fibres to disentangle, clean and intermix them to produce a continuous web or sliver suitable for subsequent processing

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS